CONCRETE COATING

Chemical compound that is applied to concrete surfaces to protect them from damage like dropping heavy tools/weights or chemical stains, damage from oil, harsh, grease and enhance their appearance.

Advantages

- Slip and skid resistant to eliminate accidents.

- Excellent for extending the lifespan of your concrete floor.

-

Usually 1-2 days installation*

This time is subject to the size of the project. - Can be applied on basically any inside/outside floor: residential garages, patios, driveways, basements, stairs, walkways and commercial floors.

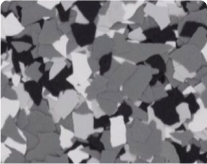

Membrane styles

Concrete Coating Finishes

Orbit

FB-310

Domino

FB-411

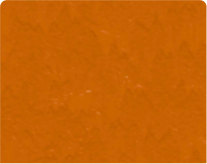

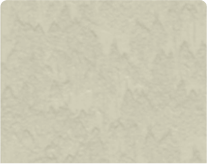

Shoreline

FB-421

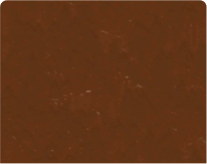

Outback

FB-517

Wombat

FB-616

Ask us for more available tones.

Methalic

Brass

Bubblegum

Cairo

Canary

Charcoal Pearl

Coffee

Concord Grape

Copper

Dark Green

Elite Crete Systems Blue

Green Apple

Gunmetal

Blak

Orange Gold

Red Yellow

Rialto

Russet

Sherbet

Sky Blue

Titanium

Ask us for more available tones.

Polyurea VS Epoxy

Epoxy and polyurea are two popular types of coatings used for concrete surfaces, but they have distinct differences in terms of composition, performance, and application. Here's a breakdown:

1. Material Composition

- Epoxy: Made from a combination of resin and hardener, which chemically reacts to form a rigid plastic material. It’s a thermosetting polymer.

- Polyurea: Derived from the reaction of an isocyanate and a resin blend, creating a highly flexible and durable coating. It’s a type of polyurethane.

2. Durability & Flexibility

- Epoxy:

- Durable but rigid. Prone to cracking under heavy impacts or shifting substrates.

- Suitable for indoor use, as it doesn’t handle UV exposure well without yellowing.

- Polyurea:

- Extremely durable and flexible, making it resistant to cracking even in environments with temperature fluctuations or substrate movement.

- Highly UV-stable and ideal for outdoor applications.

3. Cure Time

- Epoxy:

- Longer cure time (several hours to days), allowing more time for application.

- Requires careful planning since the surface is out of service for a while.

- Polyurea:

- Very rapid cure time (minutes to hours). Ideal for projects that need fast turnaround.

- Demands quick application, so it’s better suited for experienced professionals.

4. Chemical Resistance

- Epoxy:

- Resistant to many chemicals but less so than polyurea.

- Can degrade over time with exposure to certain solvents or acids.

- Polyurea:

- Superior chemical resistance, even to harsh industrial chemicals, oils, and solvents.

5. UV Resistance

- Epoxy:

- Poor UV resistance; tends to yellow and degrade when exposed to sunlight.

- Polyurea:

- Excellent UV resistance, making it suitable for outdoor environments like driveways and patios.

6. Temperature Tolerance

- Epoxy:

- Limited temperature tolerance. Extreme heat or cold can cause degradation or cracking.

- Polyurea:

- Withstands a wide temperature range, from freezing cold to extreme heat.

7. Cost

- Epoxy:

- Generally more affordable upfront but may require more maintenance over time.

- Polyurea:

- Higher upfront cost but longer-lasting, with lower maintenance needs.

8. Application

- Epoxy:

- Slower application process due to its longer working time.

- Ideal for smooth, controlled finishes on indoor surfaces like garages or basements.

- Polyurea:

- Requires specialized equipment and experienced installers due to its rapid curing time.

- Great for high-traffic areas, industrial settings, or outdoor surfaces.

Some applications

Get a free estimate

Contact Us

We are MID-OCEAN GROUP LLC, we are located in Morris Plains, New Jersey. But we offer our services to New York and Pennsylvania. We are here to help your dream ceilings and floorings come true. Have a question? Feel free to contact us via phone, email or the form below.

200 Speedwell Ave, Morris Plains, NJ. 07950

midocean.cyc@gmail.com